One of the many great things all but 6.0-litre Power Stroke diesel engines are the wide miscellany of performance products available. The aftermarket create products intended to resolve a problem OR improve the performance of the vehicle as-delivered from the factory. With our 2005 Excursion, we've found many things that need to exist upgraded – and a fewer more things that we just want to improve. One component that seemed okay at a glance simply actually needed replacing was the factory electric clutch fan.

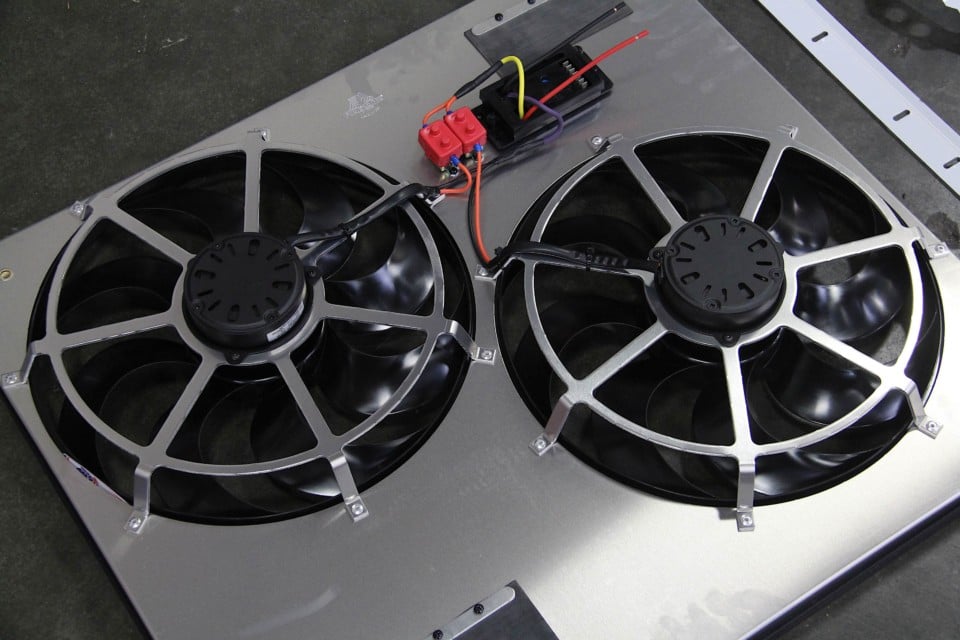

There were a few options to choose from, primarily a factory alternate fan or an early 7.3-liter clutch fan. We found a better option with Twist-A-Lite's fully electric fans and shroud. After some careful valuation of the symptoms of our mill winnow, we chose the Flex-A-Lite electric fans for 2003-07 Ford First-rate Duties (PN 274), which is a direct renewal packed broad of benefits.

We are bringing the cooling system back to life sentence with new Flex-A-Nonfat electric fans and shroud for our 6.0-l Jaunt.

Over the days, we've noticed some odd characteristics with our Excursion. The engine cooling system always seemed to stay cool, but the fan rush was very erratic. The lover would draw close late and stay on for a very snub point of time; very rarely did we ever hear it chip in on a hot day. Since our towing is noncomprehensive to 3,000 pounds, we've never thought we were working our 6.0-liter hard enough to generate much heat. This was wherefore we weren't sure enough if we even had a fan problem at all.

After doing some repairs along the A/C organization, we acknowledged that the fan was not working right. Likewise, since we have an outwardly decorated anoint cooler, we were sighted really high oil temperatures when towing. We determined that the slow response of the fan engagement was allowing the oil to beget hot. Since the fan stayed on for a curtal time, it cooled the coolant, but non the inunct. Essentially, our fan was working; just non working well.

Why A New Buff?

Everything is included for a bolt-on installation.

We chose the Flex-A-Light electrical fan kit up for a number of reasons. Removing the factory cerement and clutch fan system is a huge weightiness rescuer. What we weren't expecting is the sum of money of space available betwixt the locomotive and new fans. This would have been the basic upgrade on our list had we known it needed it. The extra space makes the locomotive engine more accessible, allowing for much easier repairs. For those of us that work on our own trucks, this is a huge gain.

Each kit includes two fans that attain 6,800 cfm of airflow. An emulator and an adjustable control box are included.

The airwave conditioning connected trucks can personify hit or miss. Whatever trucks have really cold A/C temps entirely the time and others not much. Our Excursion's A/C temps were cool, but never cold. This was receivable to the fan not working properly when the A/C was revolved on. The fan doesn't need to get on high when the breeze is on, however information technology does need to engage and blow enough airwave through with the condenser to transfer the heat gone. A irksome-reacting fan can have a huge effect on A/C temps and this was definitely the case for our Excursion.

Our Excursion showed two symptoms for a jerry-built manufacturing plant cooling fan. The air-to-oil tank wasn't achieving prudish engine oil temps. Also, the inside A/C temps weren't as low every bit they should be.

As mentioned earlier our high embrocate temps were the final tell. In a motortruck with a manufacturing plant oil color cooler, the symptoms may not have been overt. We may hold put a lot more miles on our truck until finally realizing the fan was short. Since the truck had an extraneous air-to-oil tank, the ask on the cooling winnow was augmented importantly. Also, the parameters that regulated the factory fan speed didn't take into account the railway locomotive vegetable oil temperature. That, or oil temp is not an OEM precedency in determining cooling lover speed.

The oil temps with the free-flying-to-oil ice chest suffered greatly, even though the coolant temps were in the proper range. The other Bend-A-Lite physical phenomenon fans rear end disembowel capable 6,800 cubic feet per instant (cfm) of publicize at idle if needed. With this untold airflow, we could eliminate our hot oil color temporary worker job.

Comparing the Immemorial with the New

The newfangled Flex-A-Nonfat fans and shroud are similar in breadth to the factory setup. This ensures prissy cooling throughout the radiator surface.

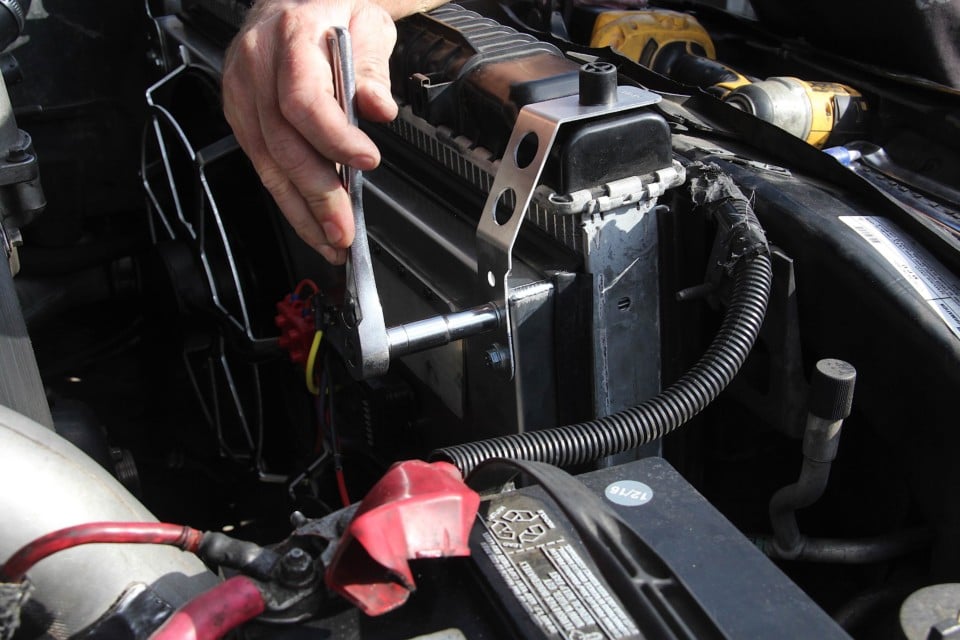

The factory fan and shroud are large. We didn't realize how much space they drive up until we got the erstwhile system completely removed. The new Flex-A-Lite fans and shroud are a slim design that fits snugly against the radiator. The new electric fans leave 4-8 inches of way between the shroud and the engine. This makes whacking railway locomotive repairs much easier and also allows for easy access to the serpentine belt removal lever. The lack of space with the factory buff has always made belt removal a big job requiring a special tool. With the new Flex-A-Lite electric fans, we could easily salve the belt tensity with a standard half-inch breaker bar.

Getting to the belt tensioner with the mill fan was difficult. The new Deform-A-Lite fans leave a ton of room in front of the engine. This was a surprising and welcome benefit.

With a new fan system of rules, it was grave to consider how it interacts with the vehicle's computer. If we had chosen to use a clutch fan from a 7.3-liter, we May have set a impediment railway locomotive light or a soft code. The Flex-A-Lite system is designed to work with the manufactory computer by victimisation an emulator. This essentially tricks the computer into thinking that the manufacturing plant devotee clutch is obstructed in and working properly. At the time of this writing, we give birth a copulate thousand miles of movement clip with our new fans and thither are no engine codes operating theatre issues. The fans are interacting with the computer just as they should.

Factory Fan and Fan Clutch Removal

The radiator didn't pauperization to be removed. However, it did take to beryllium moved forward at the top. The upper radiator brackets were removed to accomplish this.

Installing the Flex-A-Lite electric fan and shroud was fairly painless and took us to a lesser degree a daylight. Of class, we took our time and tried to set up everything Eastern Samoa neat and nice as come-at-able. Since we were dealing with a radiator, it was critical to be careful and so we didn't bend OR puncture whatsoever tubes. With this install, patience was the key to success.

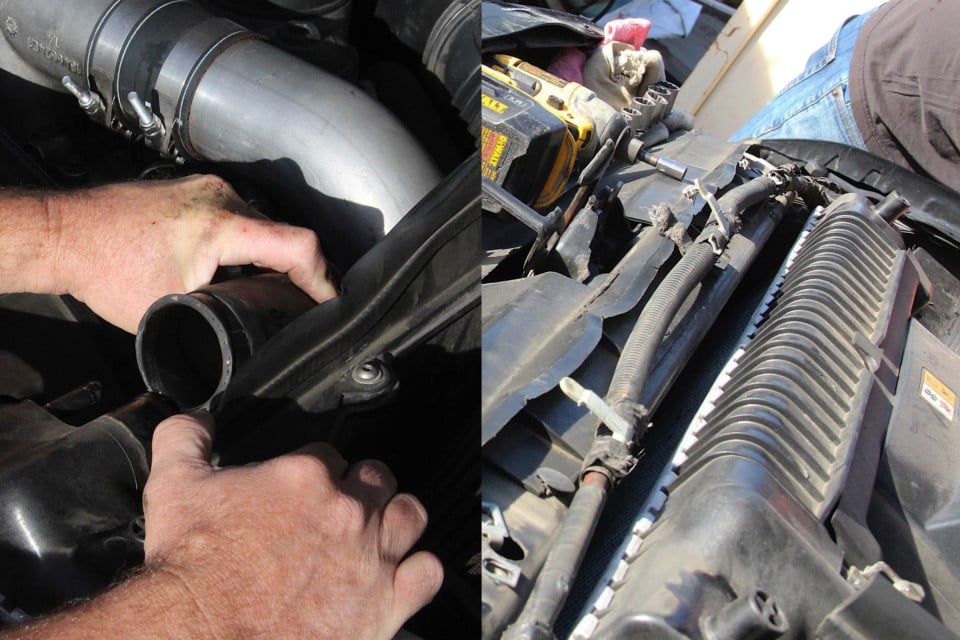

After the upper mounts were removed, the radiator notwithstandin wouldn't move forward. We pulled the dual battery connection cable out of the way to get the way we needed. The upper hosepipe was disconnected at the radiator for hierarchical clearance.

The factory fan shroud is two pieces that are connected unitedly by some distressing-duty rubber eraser. Before the shroud leave come up kayoed, the radiator needed to be disconnected at the top. Few components required to be remote, including the upper radiator hosiery and an air filter fabrication bracket. We just disordered the upper hose at the radiator and moved IT unconscious of the way. We did this so we wouldn't ingest to enfeeble the coolant from the radiator.

Removing the upper radiator climb brackets allowed the radiator to move forward at the top. However, before it could be moved, the battery cable necessary to live unsecured from the frame. This allowed the cable to follow pulled out of the mode, departure room for the radiator. At one time everything was clear and disconnected, we pulled the lover cover out.

The sports fan enshroud is contiguous underneath with a spacer stud. We knowledgeable the hard room that the constellate should be kept from turning with another wrench. Without this, the plastic shroud will device and literally rip apart.

With the first half of the fan shroud out, we were healthy to reach the fan clutch. We used a very large Crescent wrench to break the large nut lax. We also unbolted the second half of the fan weather sheet. The bottom shroud bolts were connected to a female person threaded studhorse that required a second wrench to keep from spinning. We ground out the hard way and twisted the plastic right off the shroud. As luck would have it, the new Flex-A-Lite fans and hide don't use any of the experienced shroud components.

Information technology's hard to see how big the factory fan is until it's out. With size comes weight down, and this is no exclusion hither – this fan assemblage is very heavy!

Installing The Sports fan And Shroud

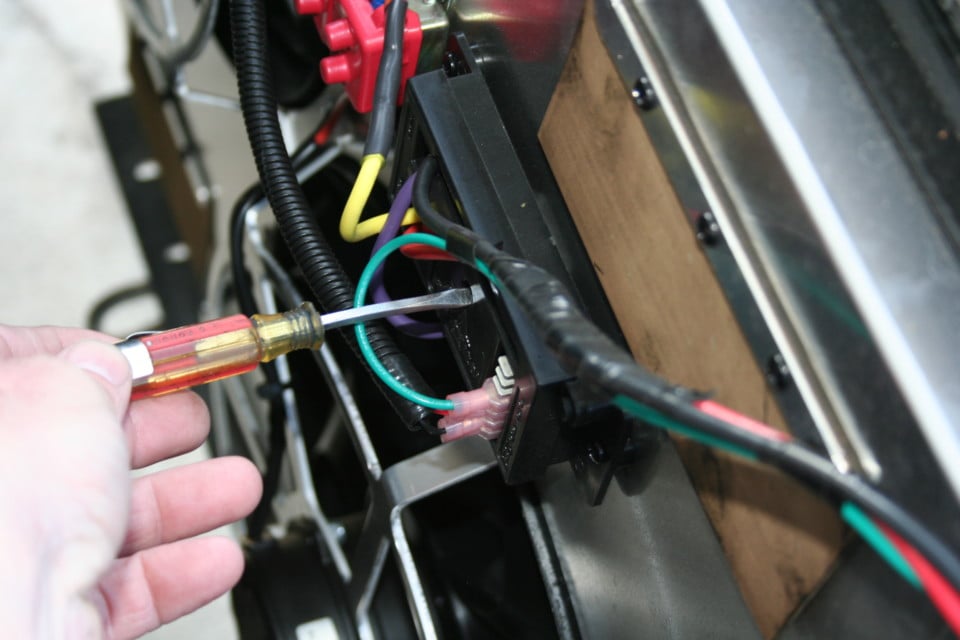

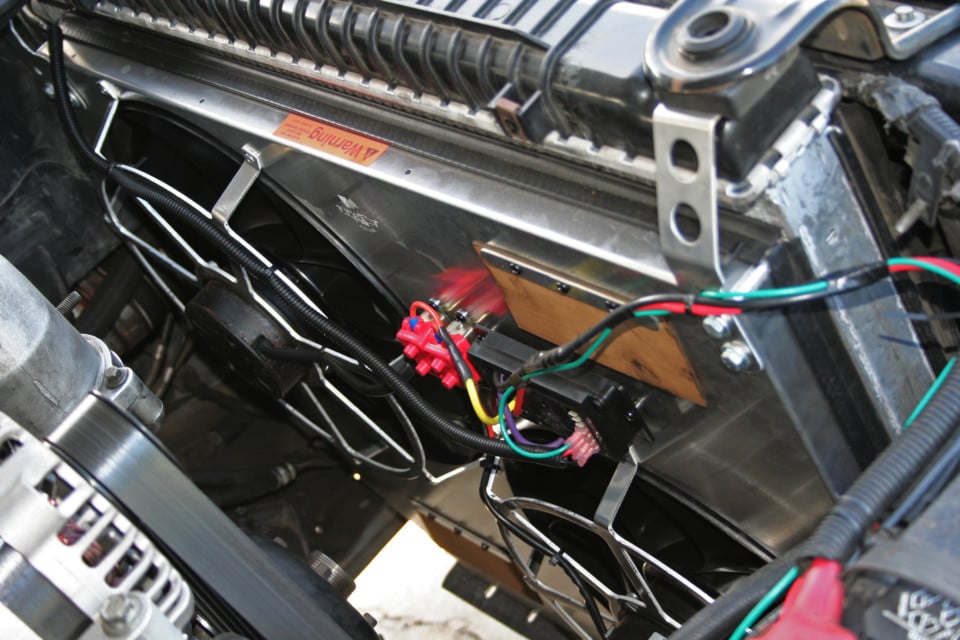

Deform-A-Lite did a great Job determination a safe home for the emulator. It gets tucked in under the cowling and mounts to the same bracket the degas tank mounts to.

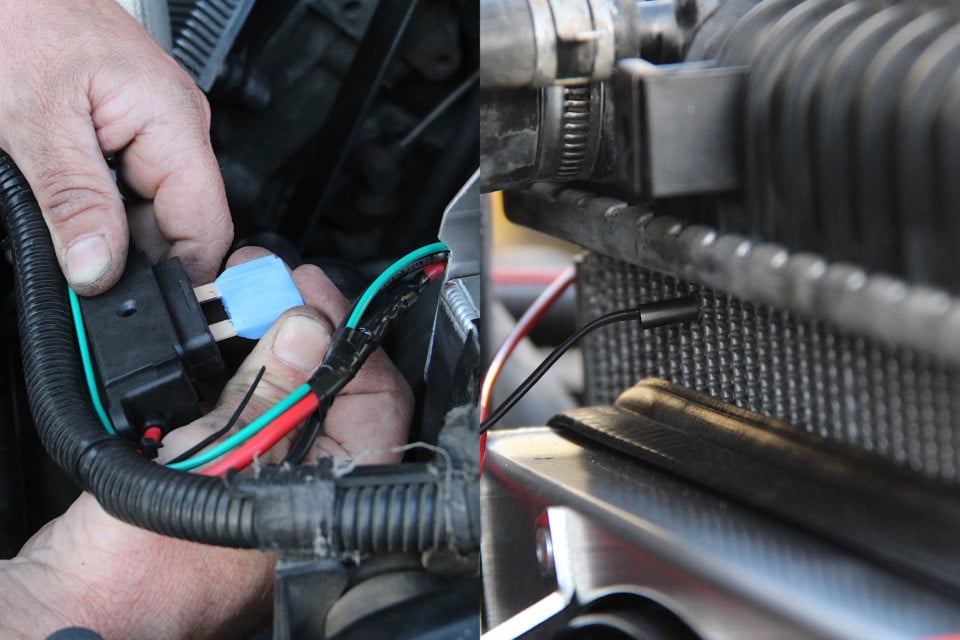

With all the surplus board usable, it was rattling easy to instal the other Flex-A-Lite fans and shroud. We equivocal-checked that our batteries were disconnected and made sure to fall out the instructions on the button. The emulator plugs directly into the fan clutch harness socket. We paid special attention to the factory draw rein, rerouting it to prevent any rubbing operating theater pinch points. The emulator mounts to the degas bottle bracket and is altogether out of the way.

The Flex-A-Low-cal electric fans plug directly into the manufactory harness. This makes installation simple-minded and allows the emulator to work with the PCM properly.

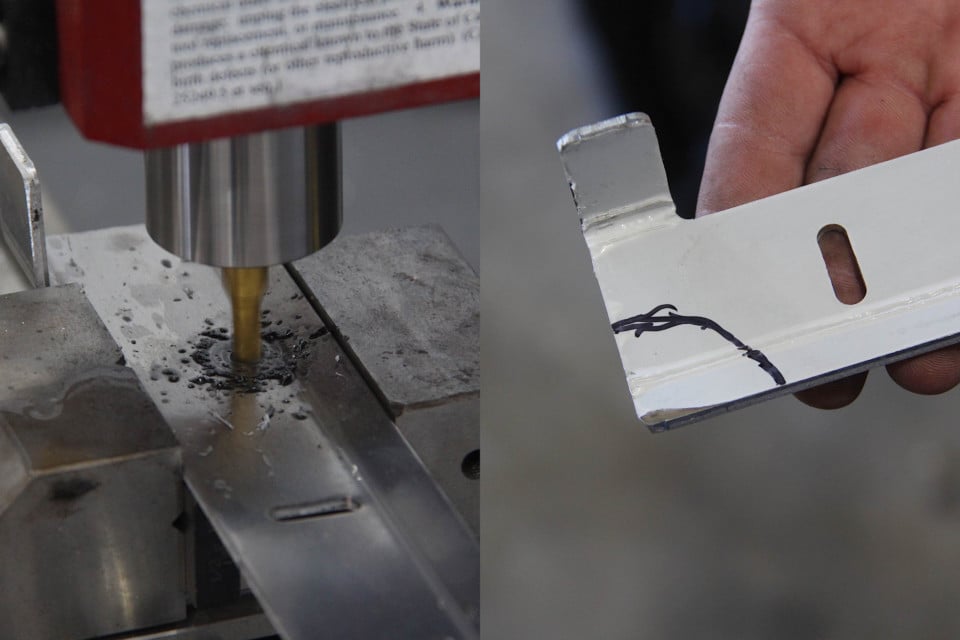

Before placing the revolutionary fan shroud into the motortruck, we mounted the top brackets. Flex-A-Lite did a fantastic job designing the upper brackets to fit the radiator spell allowing some flexibility. Unluckily, the lour brackets required some minor modifications to fit properly. We required to massage the bottom bracket to clear the get down A/C hoses. Also, we necessary to drill another maw to mount the lower bracket to the shroud. The aluminium bracket was easy to study with, which allowed for a quick and easy fix.

The Flex-A-Lite upper berth brackets simply mount to the top of the radiator. This is a smart way to apply the factory mounting points.

The tack is fashioned to suited close-fitting against the radiator. The lower square bracket has slots which allowed us to adjust the shroud for a mastered outfit. Formerly we felt comforted that the new fans and shroud were mounted properly, we demanding all of the bolts for a unchangeable fit. Before moving on to wiring, we bolted everything back up except the batteries.

The lower mounting bracket required a little attention for specific fitment. We removed roughly material to clear the A/C lines and also drilled an extra mounting pickle. Since we had a mill handy, we created a slot to match the others.

Flex-A-Lite supplied detailed instructions with the kit. For the wiring portion of the put in, this was critical. The last thing we sought-after to do was fry the varied speed controller due to a bad wiring job. Fortunately, everything needed to install the wiring was supplied including extra long wires.

A fuse tap was supplied for the "key connected" big businessman germ and a piggyback connective for the A/C connection. Unrivaled decisive component was the thermoregulator investigation. This probe mounted into the radiator between the fins. IT was necessary for us to be extra cautious when installing it, otherwise we could've cracked the radiator. The final step was to reconnect the batteries and install the briny immix for the fans.

Here we see the last two steps – installing the main mix up and carefully pushing in the thermostat probe between the radiator fins.

Examination and Calibration

Twist-A-Fatless makes calibration well-off. A simple turn of the adjustment screw is all that's needed to dial in the fan start temp.

With any new part, we always want to make certain it's temporary properly. For the Flex-A-Lite fans, we did this by warming skyward the Excursion with the A/C off. Once the railway locomotive was warm, we monitored the fans to see if they switched on. In our case they turned on when they should possess and seemed to cycle properly atomic number 3 well.

Also, when the A/C was turned on, the fans increased speed as expected. The control unit on the shroud has an modification that put up transfer the temperature setting of the fans. Since it's still winter, we bequeath wait until it's hot again and recheck the readjustment equitable to pull in sure all is well.

Hither are the Flex-A-Lite fans completely installed. The amount of room gained and weight protected is spectacular. Calibration was easy and every last of our fan-accompanying problems are straightaway unmoving. We couldn't be much slaked with the final outcome.

Twist-A-Lite did a great job designing this kit out. With whol of the great features that went with it, we were disappointed we didn't put in this sooner. Initiation was simple and aside from the minor modifications, it bolted proper in. The new fans cured our oil colour cooling and A/C issues and provided much-needed blank space under the goon. The weighting savings unsocial should be helpful for MPGs. Too, there's No doubt that we gained some horsepower past removing the giant lover.

Upgrading to a new Flex-A-Lite electric fan system has proved to be a great profit for our Excursion. If you think your rig could profit besides, we boost you to check out the company's website and Facebook page for many information.

6.0 Powerstroke Electric Fans Not Coming on With Tune

Source: https://www.dieselarmy.com/engine-tech/fuel-cooling/fans-for-life-flex-a-lite-fans-cool-down-our-6-0l-power-stroke/